Built your own Christavia MK4

- Details

- Written by: Peter Hortulanus

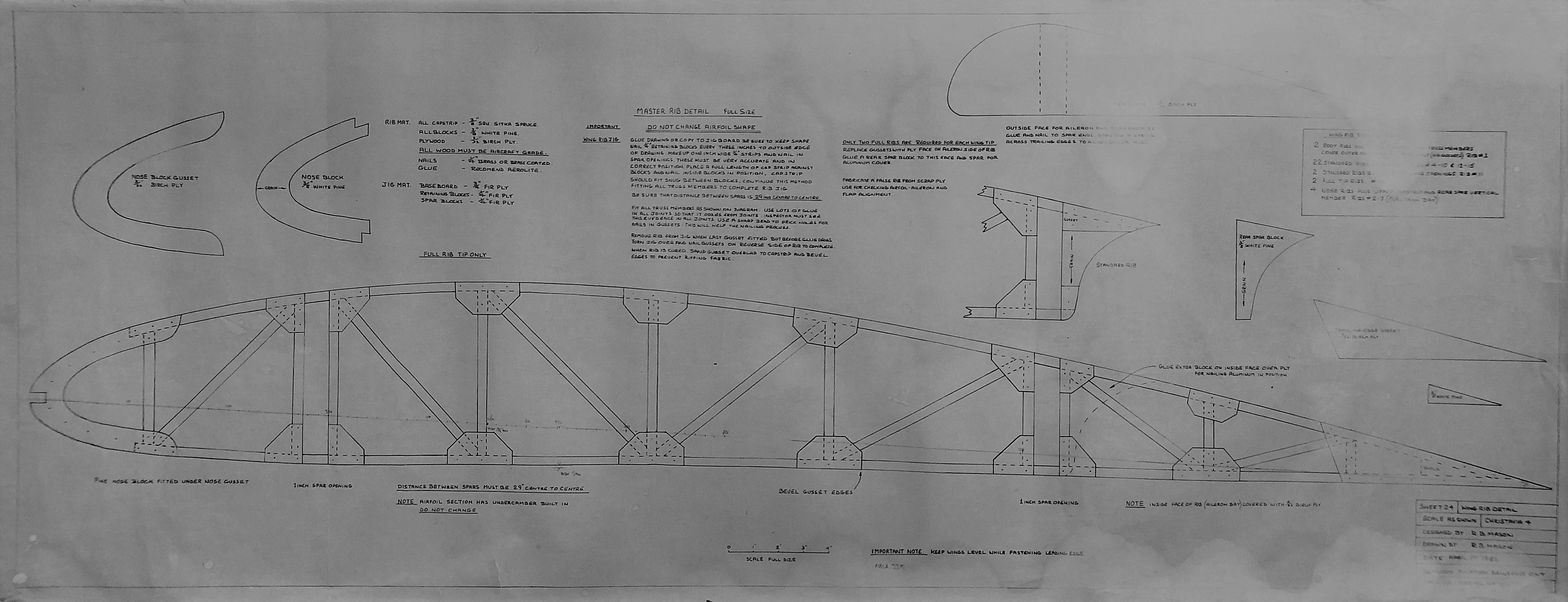

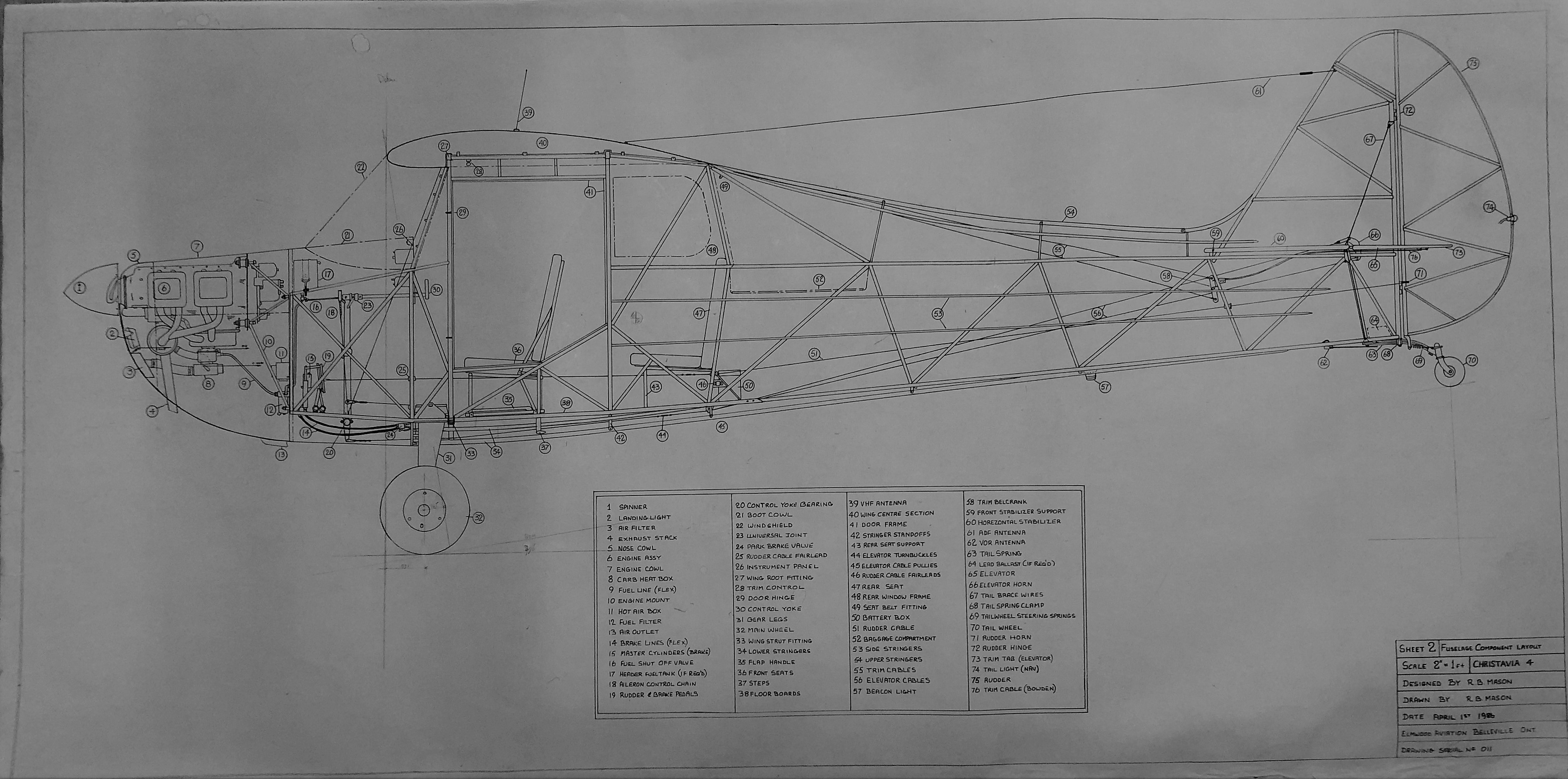

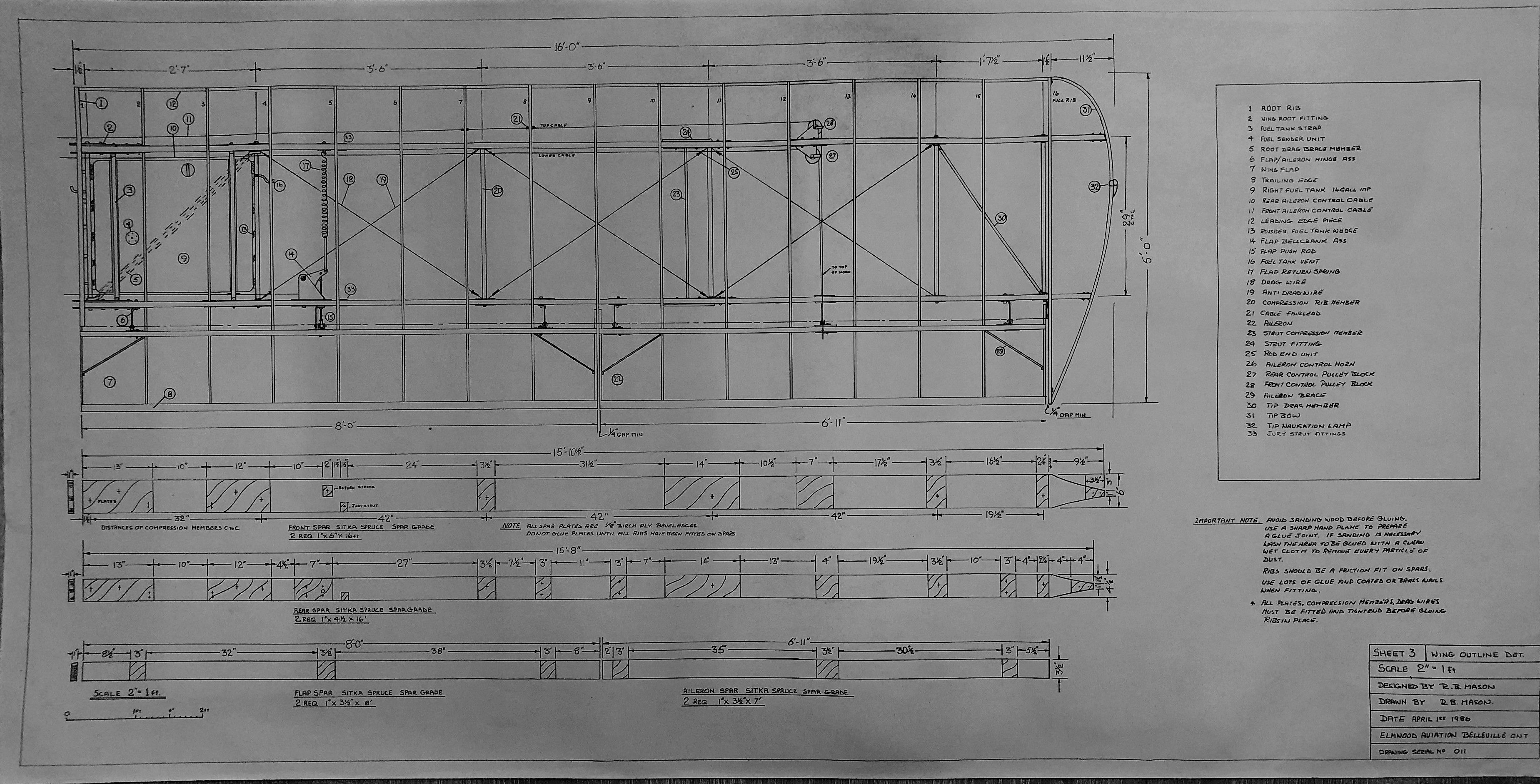

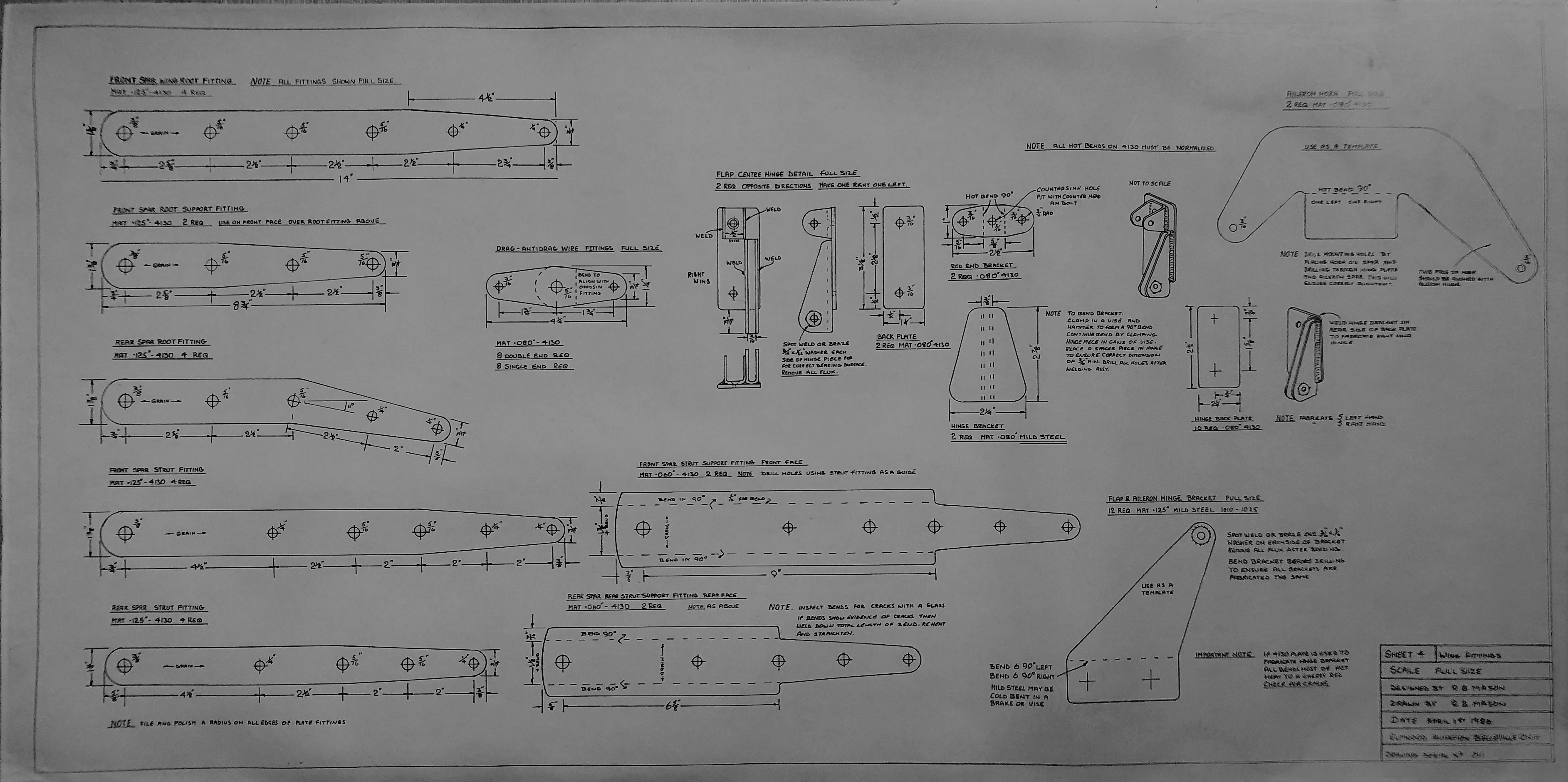

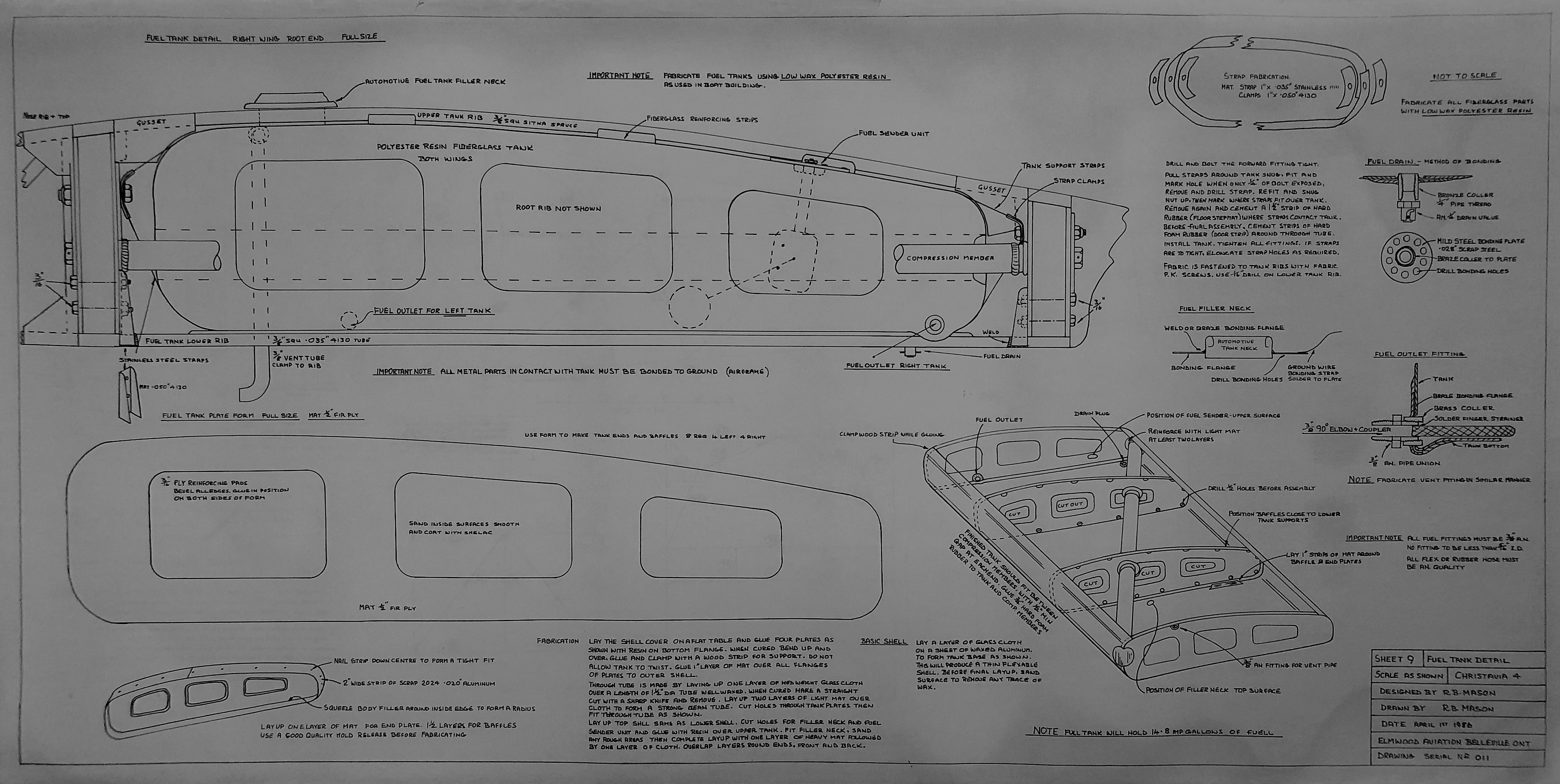

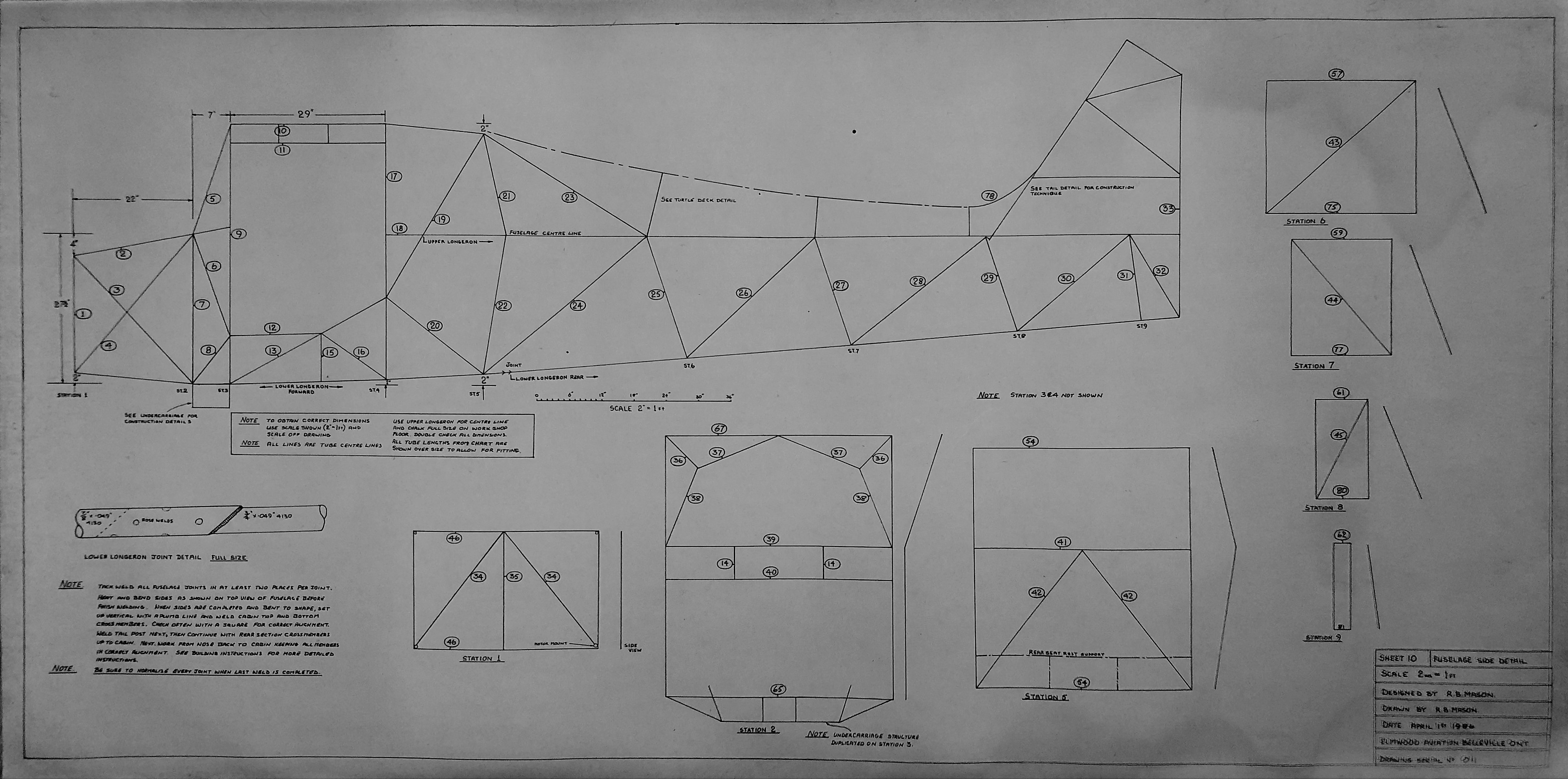

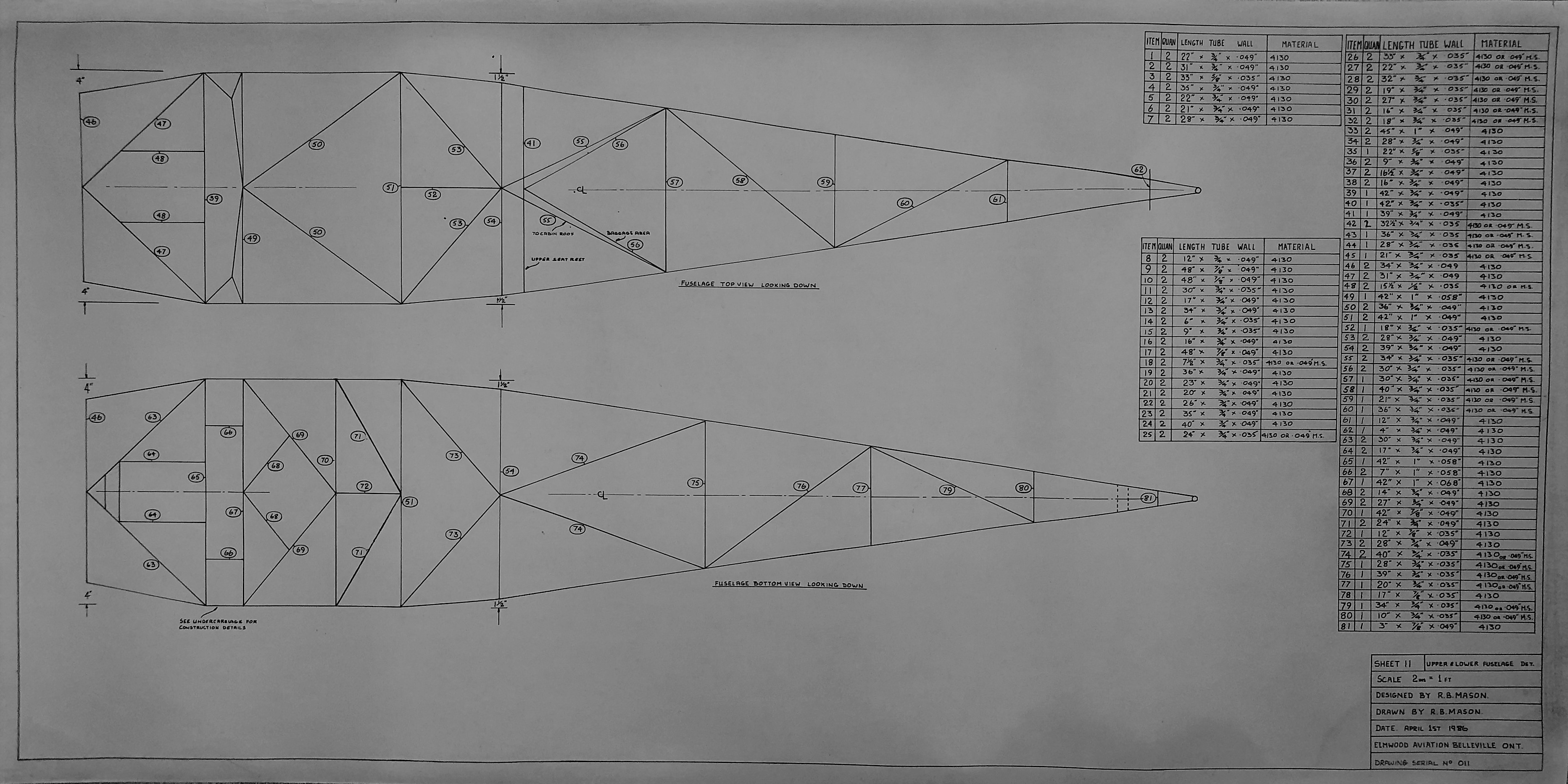

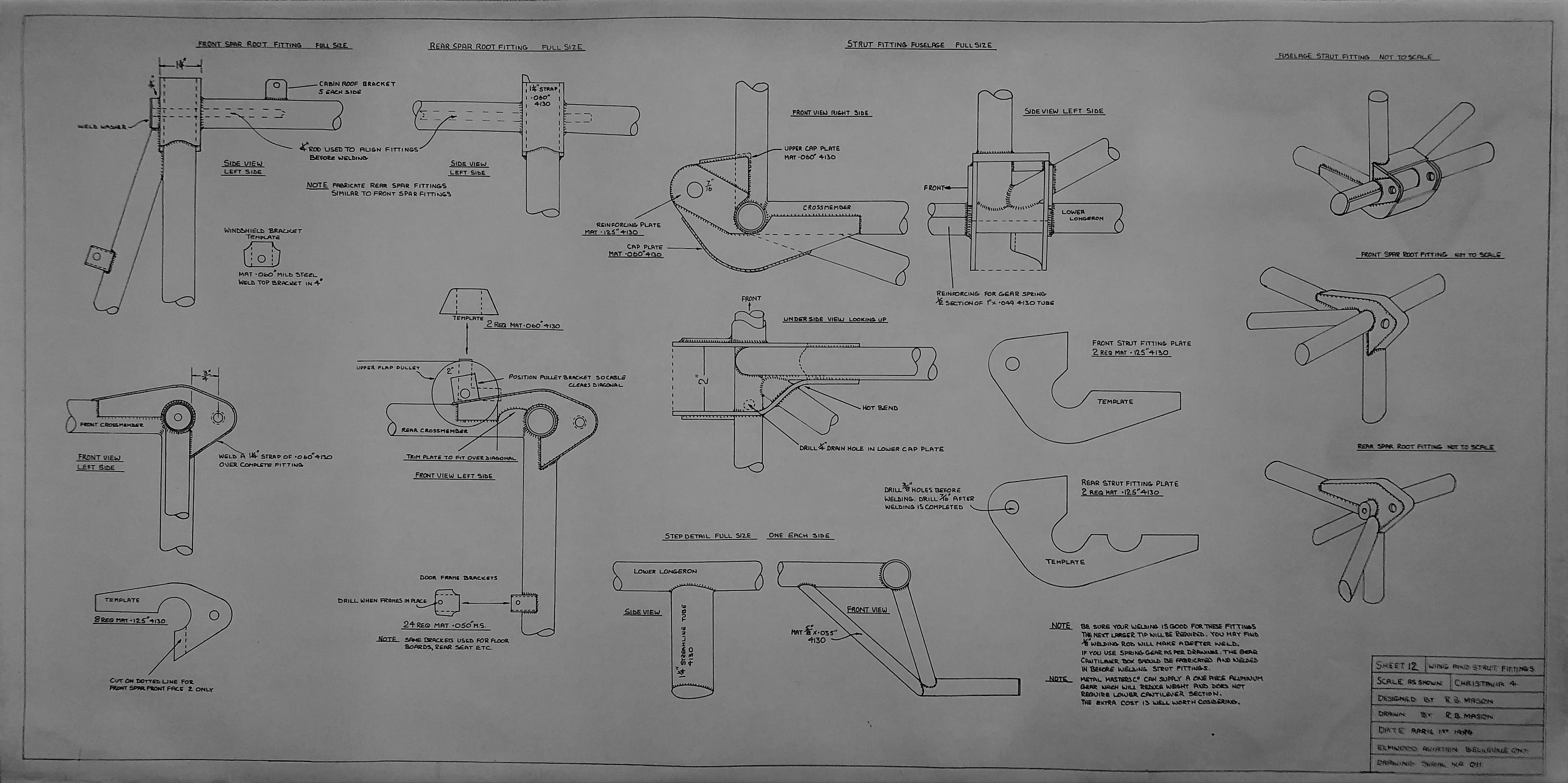

The Christavia Mk IV (Christ-in-Aviation) is a Canadian homebuilt aircraft that was designed by Ron Mason and produced by Elmwood Aviation of Frankford, Ontario (formerly in Belleville, Ontario). The aircraft is supplied in the form of plans for amateur construction.

Performance

- Details

- Written by: Peter Hortulanus

General characteristics

- Crew: one

- Capacity: three passengers

- Length: 22 ft 3 in (6.78 m)

- Wingspan: 35 ft 6 in (10.82 m)

- Wing area: 177.3 sq ft (16.47 m2)

- Airfoil: Mason

- Empty weight: 1,100 lb (499 kg)

- Gross weight: 2,200 lb (998 kg)

- Fuel capacity: 41 U.S. gallons (160 L; 34 imp gal)

- Powerplant: 1 × Lycoming O-320 four cylinder, air-cooled, or any four stroke aircraft engine, 140-150 hp (100-110 kW)

- Propellers: 2 or 3 bladed fixed or ground adjustable pitch

Performance

- Maximum speed: 130 mph (210 km/h, 110 kn)

- Cruise speed: 120 mph (190 km/h, 100 kn)

- Stall speed: 48 mph (77 km/h, 42 kn)

- Range: 400 mi (640 km, 350 nmi)

- Service ceiling: 19,000 ft (5,800 m)

- Rate of climb: 800 ft/min (4.1 m/s)

- Wing loading: 12.4 lb/sq ft (61 kg/m2)

Je eigen vliegtuig bouwen

- Details

- Written by: Peter Hortulanus

Je hebt er vast wel eens over gedroomd om je eigen vliegtuig te bouwen en dan er in te vliegen; waarheen waar je maar wilt.

Dat hoeft niet bij dromen te blijven en is eenvoudiger dan je misschien denkt.

Zelf een vliegtuig bouwen is, juist in Nederland, heel goed mogelijk.

Uiteraard moet je gekozen ontwerp en het bouwproces aan een aantal wettelijke eisen voldoen, maar dat is allemaal heel duidelijk omschreven.

Met een goede en serieuze voorbereiding zal dat geen obstakel zijn.

Uiteindelijk wordt al je inspanning beloond.

De kosten zijn te overzien en te spreiden.

Het is maar net welk ontwerp je kiest en wat voor eisen je stelt.

Je hebt natuurlijk een minimale (basis) investering nodig, maar verder kan je het zo duur maken als je zelf bepaald.

Als je een gemiddelde klusser bent en niet opziet om jezelf het e.e.a. aan te leren waar je minder handig in bent, gaat het zeker lukken.

Een verwarmde ruimte met goede verlichting, ingericht met standaard gereedschap, is alles wat je nodig hebt.

En voldoende (vrije) tijd natuurlijk.

Een vliegtuig bouwen is natuurlijk niet zomaar een "projectje"

Je moet geen haast te hebben, maar iets van een planning is wel handig, want je wil toch wel binnen een realistisch aantal jaren klaar zijn.

Afhankelijk van welk ontwerp je kiest, ben je tussen de 1500-2000 uur bezig met bouwen.

Dat lijkt veel, maar het bouwen is ontzettend leuk en het meeste kan gewoon thuis worden gedaan.

Stel: je werkt elke week minimaal 16 uur, verspreid over de week, dan kan je binnen 3 jaar klaar zijn.

Eerlijk is eerlijk; de meeste projecten lopen langer omdat je om allerlei redenen niet consequent elke week aan je project zal werken.

Maar bedenk, dat je voor alle inspanning wel iets ontzettend geweldigs terug krijgt.

Iets waar je heel trots op kan zijn.

Je leert tijdens de bouw heel veel over vliegtuigen, vliegtuigtechniek en materialen.

Natuurlijk heb je voor het vliegen, ook in je eigen vliegtuig, een geldig brevet nodig.

Het brevet kan je behalen door bv. tijdens de bouw van je vliegtuig met een vliegopleiding te starten.

Tijdens zo'n vliegopleiding ontmoet je leuke mensen met allemaal dezelfde passie.

En leer je ook heel veel over alles wat komt kijken bij het vliegen, vliegtuigen en vliegtuigtechniek.

Al die kennis en contacten kan je weer prima gebruiken voor de bouw van je eigen vliegtuig.

Droom niet langer

En stap in de dynamische wereld van vliegen en vliegtuigen.

Design

- Details

- Written by: Peter Hortulanus

Designed for African missionary work the Mark IV is a development of the Christavia Mk I, with greater wingspan, a longer fuselage and two additional seats. The aircraft features a strut-braced high-wing, a four-seat enclosed cabin with doors, fixed conventional landing gear and a single engine in tractor configuration

Wood Building

- Details

- Written by: Peter Hortulanus

Wood Basics

Sitka spruce is the most common wood used in aircraft, and contrary to popular belief, Howard Hughes’ Spruce Goose was made of birch-not spruce. Spruce has one of the greatest strength-to-weight ratios and is considered the cream of the crop of natural aircraft building materials. Western hemlock is 14 percent stronger and can be substituted for spruce, according to FAA Advisory Circular 41.13, but it’s slightly heavier and is more difficult to find.

For Sitka spruce to meet government specification MIL-S-6073, it goes through a series of inspections, starting with experts who supervise the sawing and milling of the lumber at the source. The lumber is kiln-dried to another government specification, AN-W-2. This spec says the wood must have a specific gravity greater than .36, a minimum density of 24 pounds per cubic foot, grain slope no steeper than one in 15, and a moisture content between 10 and 17 percent. This Type A wood is approved for use in any aircraft application, including use as supercritical spar material. Type B specs-lumber that is slightly less dense and may have more grain slope-can still be used in some applications, but not in any primary load structures.

Plywood is another common aircraft building material. It covers the wings of the aerobatic One Design and the fuselage of the Falco, and the gussets that strengthen wood wing ribs and fuselage structures are made from it. This is not hardware-store-variety plywood, mind you, but Mil-Spec aircraft-grade made from imported African mahogany or American birch veneers laminated in a hot press using waterproof glues. The core of aircraft-grade plywood is usually poplar or basswood.

Lest you think corrosion is something that only happens to metal, wood can also develop a sort of organic rust. Known as dry rot, this fungus is caused by too much moisture content and can render wood unusable. So when you store your wood-especially if your building project will span the course of several years-keep it in a well-ventilated area. A place with about 12 to 15 percent relative humidity is best, because wood that gets too dry can become brittle.

Alternatives to Sitka Spruce (Ref: Article from Sport Aviation December, 1998 by Ron Alexander)

If Sitka Spruce is so difficult to obtain why not find alternatives? A valid question and certainly a number of alternatives to spruce do exist. First of all, lets look at what type of wood can be used to replace spruce within an aircraft structure. Understand that written information regarding the use of wood in aircraft is limited.

The primary source of information for the builder may be obtained from FAA Advisory Circular 43-13, government bulletin ANC-19, and from a copy of Mil-Spec-6073. Advisory Circular 43-13 lists a number of different types of wood that may be used in an aircraft structure. Some of these are Douglas Fir, Noble Fir, Western Hemlock, White Pine, White Cedar, and Yellow Poplar. I will discuss the ones that are the most readily available—Douglas Fir, White Pine, and Western Hemlock.

As noted in the comparison chart in Figure 1, Douglas Fir is a very acceptable alternative for spruce. Its strength exceeds spruce by roughly 23%. Advisory Circular 43-13 states that it may be used as a substitute for spruce in same sizes or slightly reduced sizes providing the reduction in size is substantiated.

Fir does have a tendency to split making it somewhat more difficult to work. It is also heavier than spruce—about 26% heavier in fact. Remember, you are allowed to use a smaller dimension due to the increased strength. Years ago, a number of aircraft manufacturers would route out a portion of a fir spar to save weight.

Boeing used that method on a number of PT-13 and PT-17 trainers.

Can you purchase good Douglas Fir? Some lumberyards will have a good supply at a reasonable price. Most aircraft supply companies find it just as difficult to obtain Douglas Fir as they do Sitka Spruce.

The cost from an aircraft supply company will be about the same. You may find Douglas Fir cheaper at a lumberyard.

What about White Pine? As you can see from the chart White Pine is 85-96% as strong as spruce. It is easy to work with and is somewhat available. A number of kit manufacturers are using White Pine successfully within their designs. It is low in hardness and shock resisting capability. It cannot be used as a direct substitute for spruce without an increase in size to compensate for the lesser strength.

Western Hemlock has been used in the construction of aircraft for a number of years. The popular Pietenpol airplane used Western Hemlock in constructing spars for a number of years.

The strength properties slightly exceed spruce and the wood may be used as a direct substitute for spruce. FAA Advisory Circular 43-13 notes that it is less uniform in texture than spruce.

Concerning the comparison chart in Figure 1, two definitions are in order. A ring per inch is a measure of the rate of diameter growth of a tree. These rings correspond closely to yearly increments of growth of the tree. See Figure 2. They are not necessarily definite criteria for

strength. Mil-Spec-6073 defines the number of rings per inch needed for spruce that will be used in an aircraft structure. According to government bulletin ANC-19 – Wood Aircraft Inspection and Fabrication—it states "Rejection of material on the basis of the number of rings per inch is somewhat arbitrary, because it does not always reflect the strength of the piece."

Maximum grain slope is the deviation of annual growth rings from parallelism with the longitudinal axis of a piece of wood. See Figure 3. Looking at the face of a board the growth rings should not slope upward or downward more than the specified amount, usually 1 inch in a

15-inch length of the wood. This slope of grain is usually termed diagonal grain. Both of these will be discussed in detail in the section pertaining to inspection of wood.

CHART OF WOODS FOR AIRCRAFT USE

TYPE OF WOOD STRENGTH MINIMUM RINGS PER INCH MAXIMUM GRAIN SLOPE

Sitka Spruce 100% 6 1:15

Douglas Fir Exceeds Spruce 8 1:15

White Pine 85-96% 6 1:15

Western Hemlock Slightly exceeds spruce 6 1:15

INSPECTING WOOD FOR AIRCRAFT USE

If I cannot obtain spruce or any other wood that is certified for use on aircraft how do I know I have the correct quality?

The answer is you don’t. You must find someone familiar with inspecting wood or learn more about it yourself.

Now, there is certainly a difference between production aircraft and experimental aircraft concerning legalities.

There is, however, no difference in concerns for high quality.

Production aircraft must verify a source for all materials that are used as a replacement for original parts.

That means very simply that you should be able to track the origin of the wood that you will be using to replace a spar in a production airplane, as an example. Since wood is not stamped "certified for aircraft use" what does the FAA want in the form of paperwork to

verify you are placing the proper type of wood on your airplane? Most of the inspectors I have contacted agree that a copy of the grading certificate stating that the shipment of wood that included your spar material meets Mil-Spec-6073.

As far as actually certifying the wood as being legal to be placed upon your airplane that is the responsibility of the A & P mechanic and

ultimately the IA who returns the aircraft to service after the repair.

Some companies will actually manufacture a spar for replacement on a certain type of airplane.

This should be done using a PMA number (Parts Manufacturing Authority).

That satisfies the requirement for origin of the part but it must still be inspected and authorized by the IA.

As you are probably aware, the materials used in experimental aircraft do not have to meet any legal requirements.

That does not exempt the builder from using common sense and good judgement.

In other words, even though I do not have to verify the origin of the wood used in an experimental aircraft I will want to do so.

I would strongly encourage the builder to thoroughly inspect the final piece of wood for defects prior to installation.

Now, the builder of an experimental aircraft can go to a local lumber yard and purchase spruce, fir, or white pine.

If you are purchasing spruce make sure it is Sitka Spruce. No grading certificate is required and usually cannot be obtained because an expert does not grade that wood. There is nothing wrong with purchasing wood from a lumberyard as long as you know what you are buying. In other words, you must become familiar with allowable defects and tolerances regarding the use of wood in aircraft.

This will be accomplished by acquiring information through AC43-13, ANC-19, Mil-Spec-6073, etc. to ensure you know what is safe in your airplane. If you do not feel confident in performing this inspection, find someone who is knowledgeable concerning aircraft wood.

I will outline the proper procedure for identifying and inspecting wood for use in aircraft. This will help you familiarize yourself enough with the major defects to be able to identify them and know that the wood you are using is safe. I will be quoting largely from Mil-Spec-6073, a document that can be purchased through Aircraft Spruce & Specialty. The Forest Products Laboratory also has a wealth of information concerning wood in general. They have been very helpful to the EAA and to custom builders in general. Ben Owen and his group of knowledgeable people in Information Services at EAA Headquarters also have a lot of good information regarding aircraft wood.

Marquart Charger MA-5

- Details

- Written by: Peter Hortulanus

The Marquart MA-5 Charger is a biplane designed by Ed Marquart (d. 2007) in the late 1960s. It is a sport biplane in the finest sense of the word: easy to handle, gentle but responsive to fly, and easy to land.

Inspired by the Stampe SV.4 and Bücker Bü-131 Jungmann biplanes of the 1930s, the design of the Charger calls back to a time when flying was a stylish affair; when the pilot would leap into the cockpit with leather helmet, goggles, and white silk scarf casually draped around the neck. With swept wings, cantilever landing gear, and a long, tapered tail, the Charger strikes a distinctive stance on the ground or in the air.

The Charger is a two-place airplane constructed of 4130 steel tube, wood, aluminum, and fabric. The fuselage is primarily of 4130 steel tubing. The wings are primarily of spruce. The covering is mostly fabric, with aluminum skin typically running from the engine to the cockpit area.

Construction is straightforward, and will be familiar to builders already familiar with tube-and-fabric construction. The design lends itself well to homebuilding, with very few specialized parts, and no machining required. The builder will need to be familiar with woodworking and welding, but very few special tools are required for the build. A typical home shop will already have many of the tools required to build a Charger. Builders typically spend 3000-4000 hours building a Charger.

Specifications

| Height | 7 ft 7 in (2.3 m) |

| Wingspan | 24 ft (7.3 m) |

| Length | 20 ft 8 in (6.3 m) |

| Wing Area | 170 ft2 (16 m2) |

| Wing Sweep | 10° |

| Airfoil | NACA 2412 |

| Design Empty Weight | 1100 lbs (499 kg) |

| Gross Weight | 1650 lbs (748.4 kg) |

| Payload | 550 lbs (220 kg) |

| Payload with Full Fuel | 391 lbs (177.7 kg) |

| Fuel Capacity | 26.5 US gal (100.7 l) |

Performance*

| Design Engine HP Range | 125-180 HP (93-134 kW) |

| Design Loading | +6/-4 G |

| Cruise Speed | 100 kt (115 mph) (185 km/h) |

| Stall Speed (Vs) | 37 kt (42 mph) (68 km/h) |

| Never-Exceed Speed (Vne) | 161 kt (185 mph) (298 km/h) |

| Best Glide Speed (Vg) | 65 kt (75 mph) (121 km/h) |

| Max Climb Rate at 1300 lbs | 1100 fpm (5.59 m/s) |

| Wing Loading | 9.12 lb/ft2 (0.385 kg/m2) |

| Power Loading | 12.4 lb/HP (7.57 kg/kW) |

| Range | 400+ miles (643+ km) |

Covering

- Details

- Written by: Peter Hortulanus

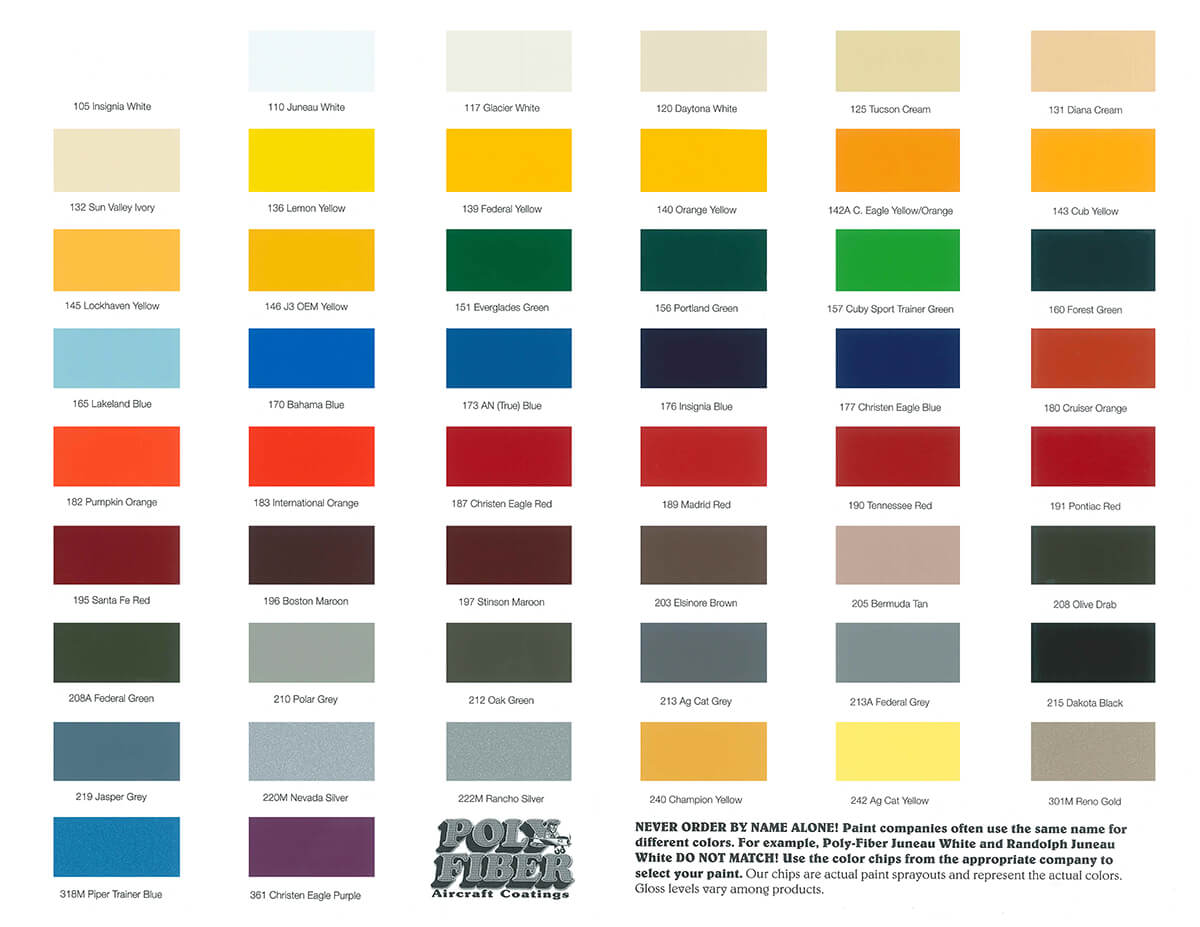

Poly-Fiber is the world's best-selling fabric-covering system.

For over forty years, the all-vinyl Poly-Fiber system has proven to be the easiest to use, most forgiving, and most durable system on the market.

The system is designed for first time users as well as experienced restorers.

Poly-Fiber lasts over 25 years in outdoor storage, does not burn, and can be applied in high humidity and varying temperatures.

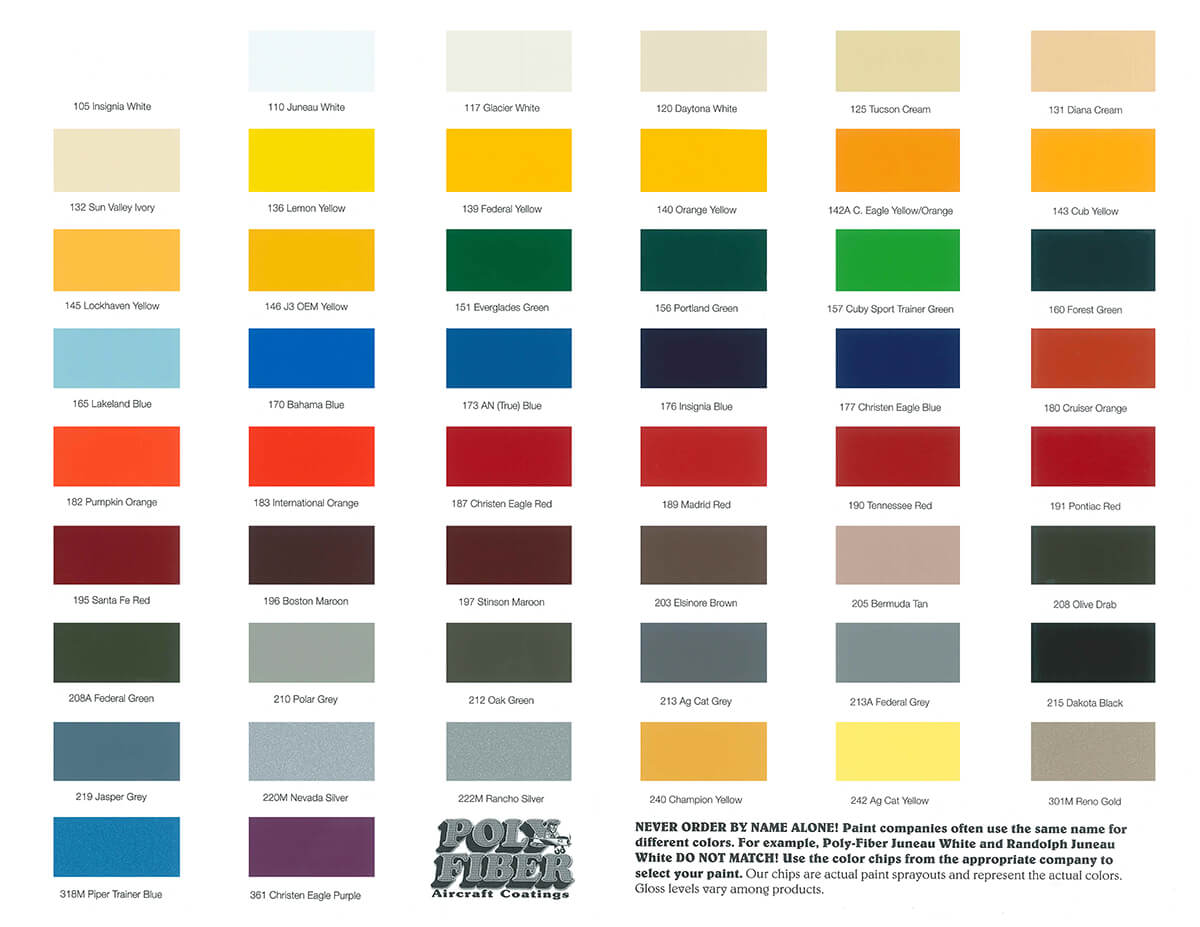

Poly-Fiber comes with a choice of topcoat paints.

Choose a classic satin finish with Poly-Tone or a brilliant high gloss with either Aero-Thane polyurethane.

All you'll need to know for an entire covering project, you'll find in the free downloadable and very detailed Manual

POLY-TAK

This is our own special proprietary fabric cement. It’s used to cement fabric together, and to cement fabric to the airframe.

POLY-BRUSH

This is our fabric sealer. It’s used for closing the “pores” of bare fabric and prepare it for subsequent coatings. It’s also used to attach finishing tapes.

POLY-SPRAY

Applied just before the final color paint, this silver coating protects the fabric against ultra violet (UV) rays.

POLY-TONE

Here’s the final color paint. It has a nice satin-gloss finish. Used over fabric, it is easy to repair. Not the best when used over metal, but it works OK with proper preparation.

MEK

The universal “fixer” solvent that cuts the four vinyl products above. It’s used to “unglue” fabric-to-fabric and fabric-to-airframe bonds. It’ll also remove any of the four products at any point in the process, and it’s handy during repairs, too. However, it’s too harsh to be used as a reducer.

R 65-75 REDUCER (Thinner)

The stuff used to thin Poly-Brush, Poly-Spray, and Poly-Tone at “normal” tem-peratures, between 65 and 75°F.

RR 8500 REDUCER

Serves the same purpose as 65-75, but works at temperatures above 85°F.

AERO-THANE

If you want a high-gloss high-tech “wet-look” finish, this is the colored paint to use. It’s a two-part product that uses it’s own U-865 catalyst and UE-820 reducer. MEK doesn’t cut it. It works great over fabric and metal, but it’s more difficult to repair than Poly-Tone.

EP-420 EPOXY PRIMER

This is our two-part catalyzed epoxy primer for use on steel and aluminum. It’s the only consistently successful primer you can use in the Poly-Fiber system. Famil-iar zinc chromate and other one-part primers will peel off after contact with the Poly-Fiber products. Not a good idea.

EV-400 EPOXY VARNISH

Serves the same purpose as EP-420 above, except this one’s for wood.

BR-8600 BLUSH RETARDER

Used to slow down the drying time of our coatings to reduce the possibility of “blush” in high-humidity environments. It also makes Poly-Tone paint glossier.

Page 1 of 2