Poly-Fiber is the world's best-selling fabric-covering system.

For over forty years, the all-vinyl Poly-Fiber system has proven to be the easiest to use, most forgiving, and most durable system on the market.

The system is designed for first time users as well as experienced restorers.

Poly-Fiber lasts over 25 years in outdoor storage, does not burn, and can be applied in high humidity and varying temperatures.

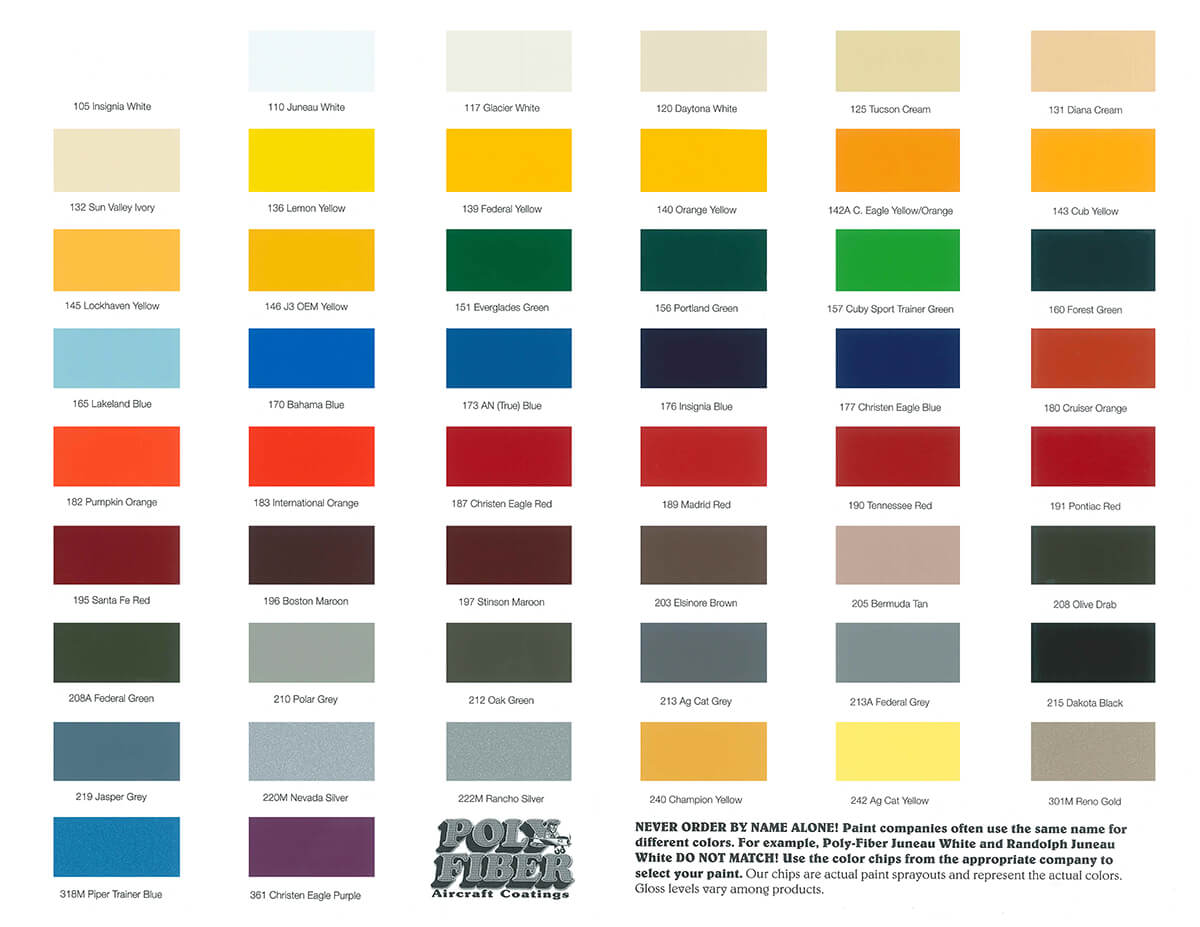

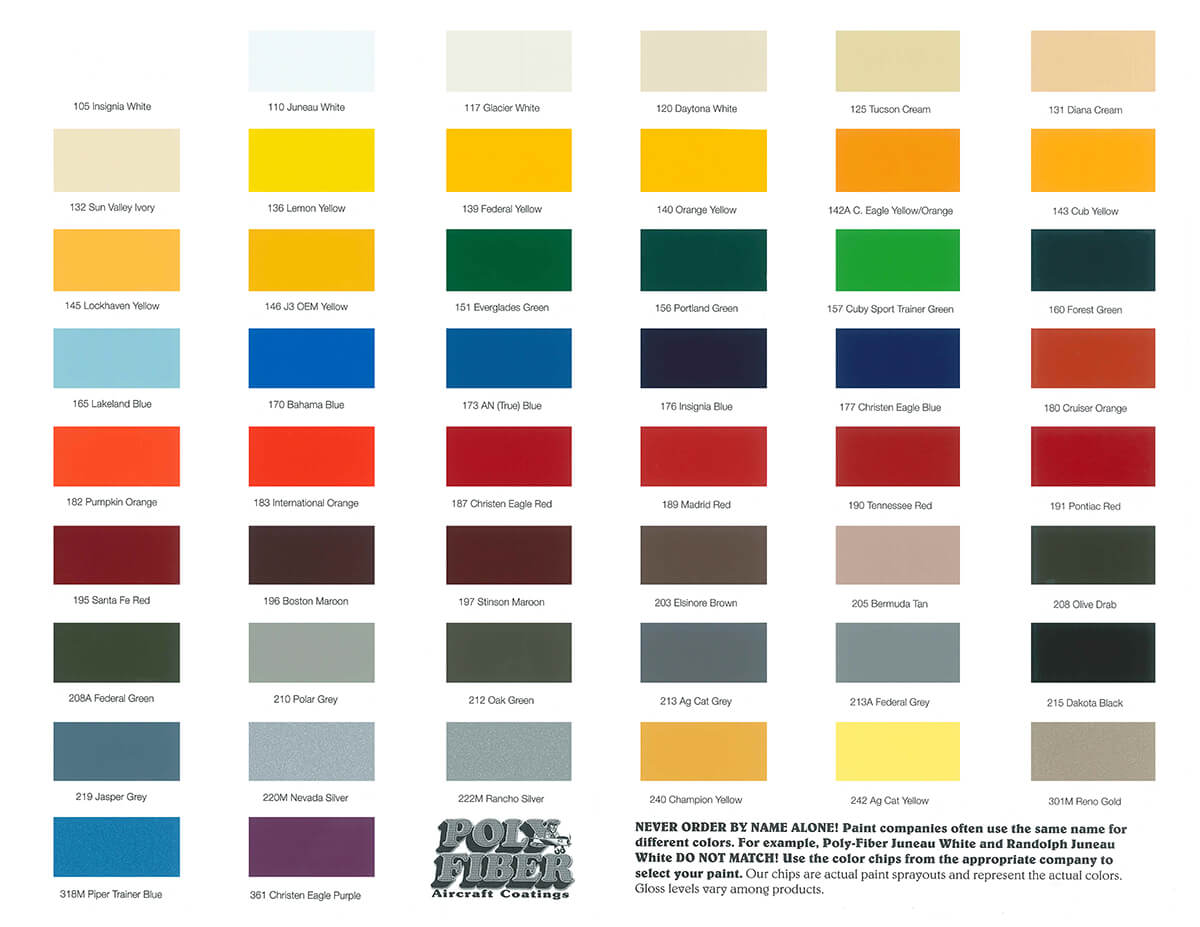

Poly-Fiber comes with a choice of topcoat paints.

Choose a classic satin finish with Poly-Tone or a brilliant high gloss with either Aero-Thane polyurethane.

All you'll need to know for an entire covering project, you'll find in the free downloadable and very detailed Manual

POLY-TAK

This is our own special proprietary fabric cement. It’s used to cement fabric together, and to cement fabric to the airframe.

POLY-BRUSH

This is our fabric sealer. It’s used for closing the “pores” of bare fabric and prepare it for subsequent coatings. It’s also used to attach finishing tapes.

POLY-SPRAY

Applied just before the final color paint, this silver coating protects the fabric against ultra violet (UV) rays.

POLY-TONE

Here’s the final color paint. It has a nice satin-gloss finish. Used over fabric, it is easy to repair. Not the best when used over metal, but it works OK with proper preparation.

MEK

The universal “fixer” solvent that cuts the four vinyl products above. It’s used to “unglue” fabric-to-fabric and fabric-to-airframe bonds. It’ll also remove any of the four products at any point in the process, and it’s handy during repairs, too. However, it’s too harsh to be used as a reducer.

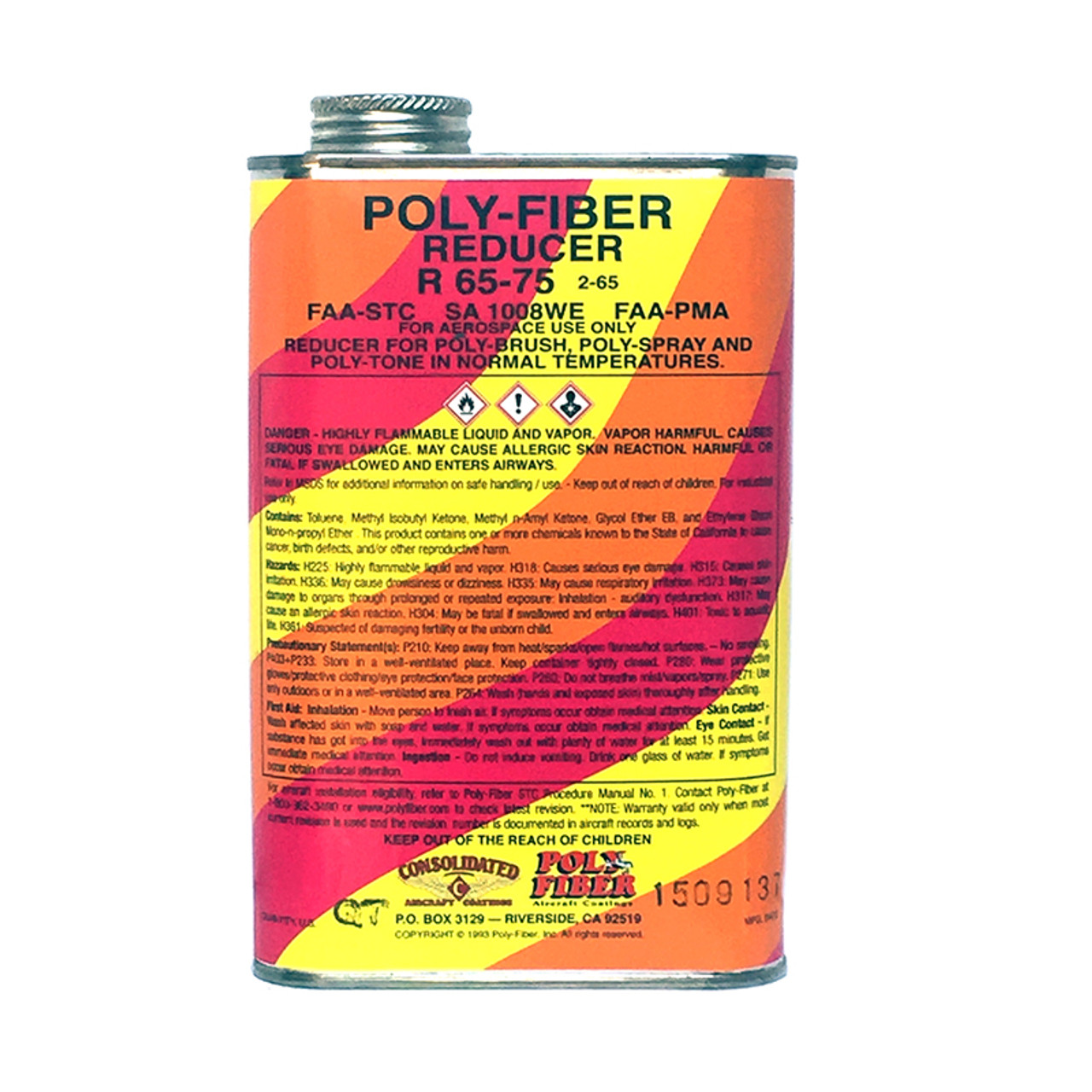

R 65-75 REDUCER (Thinner)

The stuff used to thin Poly-Brush, Poly-Spray, and Poly-Tone at “normal” tem-peratures, between 65 and 75°F.

RR 8500 REDUCER

Serves the same purpose as 65-75, but works at temperatures above 85°F.

AERO-THANE

If you want a high-gloss high-tech “wet-look” finish, this is the colored paint to use. It’s a two-part product that uses it’s own U-865 catalyst and UE-820 reducer. MEK doesn’t cut it. It works great over fabric and metal, but it’s more difficult to repair than Poly-Tone.

EP-420 EPOXY PRIMER

This is our two-part catalyzed epoxy primer for use on steel and aluminum. It’s the only consistently successful primer you can use in the Poly-Fiber system. Famil-iar zinc chromate and other one-part primers will peel off after contact with the Poly-Fiber products. Not a good idea.

EV-400 EPOXY VARNISH

Serves the same purpose as EP-420 above, except this one’s for wood.

BR-8600 BLUSH RETARDER

Used to slow down the drying time of our coatings to reduce the possibility of “blush” in high-humidity environments. It also makes Poly-Tone paint glossier.